The Future of 3D Printing: Where Innovation Is Headed Next

When I first heard about 3D printing years ago, it seemed like something straight out of science fiction. A machine that could create objects from thin air. Today, it’s incredible to see how far the technology has come, transforming industries and even our everyday lives. What once felt experimental and futuristic is now powering real-world solutions across healthcare, construction, aerospace, and more.

As 3D printing continues to evolve, it’s not just about making things faster or cheaper; it’s about reimagining what’s possible. From printing customized medical implants to building entire homes layer by layer, the boundaries keep expanding. In this paper, I want to take a closer look at where this journey is headed. By exploring new materials, artificial intelligence integration, bioprinting breakthroughs, and large-scale construction, I hope to show how 3D printing is poised to tackle some of the biggest challenges we face and maybe even inspire you to imagine the future a little differently.

In parallel, industry leaders and policymakers must address challenges related to intellectual property, quality control, and standardization to ensure the responsible expansion of 3D printing technologies across global supply chains.

1. Advancements in Materials and Processes

1.1 Expanded Material Palette

The development of new materials, including high-performance polymers, metals, and composites, is broadening the scope of 3D printing applications. Innovations in material science are enabling the production of parts with enhanced mechanical properties, thermal resistance, and biocompatibility.

Furthermore, researchers are experimenting with smart materials that respond to environmental stimuli such as heat, light, and moisture. These "4D printing" techniques open the door to dynamic structures capable of self-assembling or adapting over time, which could have profound implications for fields like robotics, aerospace, and biomedical devices.

Future developments are expected to focus on multi-material printing, where machines can seamlessly print objects combining metals, ceramics, and polymers, resulting in multifunctional products that outperform traditionally manufactured counterparts.

1.2 High-Speed and Large-Scale Printing

Technological advancements are increasing the speed and scale of 3D printing. For instance, the University of Maine unveiled the world’s largest 3D printer, capable of producing structures up to 96 feet long, facilitating applications in construction and infrastructure.

Simultaneously, methods such as continuous liquid interface production (CLIP) and high-speed sintering (HSS) are minimizing print times without sacrificing quality. These innovations are critical for scaling 3D printing into mass production environments, making it competitive with traditional manufacturing processes for high-volume output.

As printer resolution, speed, and build volume continue to advance, it is foreseeable that entire factories of the future may operate autonomously, fabricating complex assemblies layer-by-layer without the need for traditional supply chains or human intervention.

2. Integration of Artificial Intelligence

AI is playing a pivotal role in optimizing 3D printing processes. By analyzing vast datasets, AI algorithms can predict potential defects, optimize print parameters, and enhance design efficiency. Startups like Dynatomics are leveraging AI to revolutionize aircraft manufacturing through additive processes.

Beyond defect prediction, AI-driven generative design is pushing the boundaries of creativity and performance by automatically generating structures optimized for strength, weight, and material use. This synergy between AI and 3D printing is allowing engineers to explore complex biomimetic designs that were previously impossible with conventional methods.

In the future, machine learning models could enable self-correcting printers that adapt and recalibrate during the printing process, virtually eliminating print failures and achieving near-perfect first-time yields.

3. Bioprinting and Healthcare Innovations

3.1 Tissue and Organ Fabrication

Bioprinting is advancing towards the fabrication of functional tissues and organs. Researchers have successfully 3D-printed neural networks composed of living brain cells, offering potential alternatives to animal testing and paving the way for personalized medicine.

As techniques mature, the vision of transplantable 3D-printed organs becomes increasingly realistic. Customizable tissue grafts, blood vessels, and even fully vascularized organs could address the chronic shortage of donor organs and revolutionize regenerative medicine.

Additionally, innovations in bio-inks, materials laden with living cells, are expanding the types of tissues that can be printed, leading toward functional skin grafts, cardiac tissues, and perhaps even entire organ systems engineered on demand.

3.2 Microgravity Bioprinting

Conducting bioprinting in microgravity environments, such as the International Space Station, allows for the creation of complex tissue structures without the constraints of Earth’s gravity. This approach holds promise for regenerative medicine and long-duration space missions.

Future missions to Mars and beyond may rely on microgravity bioprinting not only to produce replacement tissues for astronauts but also to study fundamental biological processes in ways impossible under Earth's gravity. These findings could yield valuable insights into aging, disease progression, and tissue development.

Moreover, microgravity bioprinting could accelerate discoveries that lead to more robust tissue engineering techniques back on Earth, making advanced regenerative therapies more accessible to a broader patient population.

4. Construction and Sustainable Housing

3D printing is revolutionizing the construction industry by enabling the rapid and cost-effective production of housing. The use of bio-based materials and large-scale printers can address housing shortages and reduce environmental impact.

Additionally, additive construction techniques can drastically reduce material waste compared to traditional construction, promoting greener building practices. As sustainability becomes a priority worldwide, 3D-printed homes that use recycled or renewable materials are emerging as a viable solution to the dual crises of housing scarcity and environmental degradation.

Advances in automated site preparation, robotic arms, and modular design could soon enable entire neighborhoods of 3D-printed homes to be erected in a matter of days, redefining emergency response efforts after natural disasters and supporting sustainable urban expansion.

5. Aerospace and Automotive Applications

Additive manufacturing is streamlining the production of complex components in aerospace and automotive sectors. By reducing weight and material waste, 3D printing contributes to improved fuel efficiency and performance. Companies are exploring the use of 3D-printed parts in aircraft and electric vehicles.

Moreover, on-demand 3D printing of replacement parts for aircraft and vehicles can significantly reduce downtime and inventory costs. In the future, distributed manufacturing facilities equipped with 3D printers could produce critical components at remote locations, enhancing operational resilience for airlines, space missions, and automotive fleets.

In aerospace, additive manufacturing is also enabling the creation of next-generation propulsion systems, lighter satellite structures, and intricate cooling channels within engines, paving the way for more efficient and innovative designs.

6. Future Outlook

Looking ahead, I can't help but feel excited about where 3D printing is going. Watching this technology move from simple prototypes to life-changing innovations has been nothing short of amazing. As 3D printing continues to blend with AI, advanced materials, and smarter design tools, we’re going to see new ways of making things that were once considered impossible. It’s not just about faster production or lower costs. It's about building a future that's more sustainable, more creative, and more accessible for everyone.

I believe that as 3D printing becomes more widespread, we’ll see manufacturing become less centralized and much more personal. Imagine a world where you can design, customize, and create almost anything you need: right where you live. Of course, new challenges around ethics, regulations, and education will come with these advancements, but that’s part of the journey. I’m optimistic that by working together, engineers, scientists, policymakers, and everyday people, we can steer this powerful technology toward a future that benefits us all.

Furthermore, interdisciplinary collaboration between material scientists, software developers, biotechnologists, and engineers will be crucial in unlocking the full potential of additive manufacturing, leading to innovations that we can scarcely imagine today.

You May Also Like

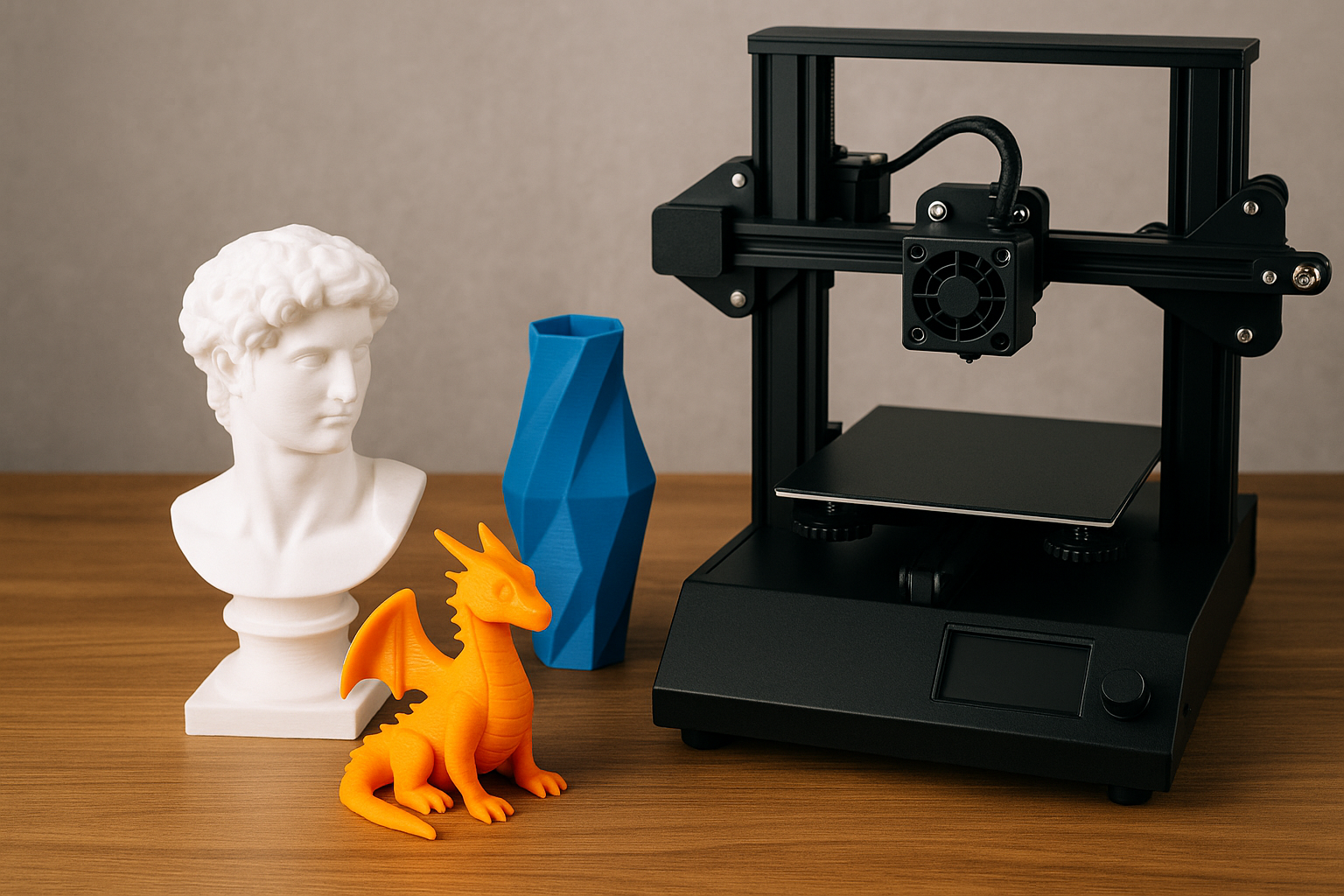

3D Printing for Hobbyists: Applications, Trends & Getting Started

Hobbyist 3D printing today offers the ability to create high-quality, complex, and functional objects at home, turning creative ideas into reality with surprising precision and versatility.

The Best 3D Printers in 2025: A Complete Buyer’s Guide

Discover the top 3D printers of 2025, from budget-friendly speedsters to professional-grade powerhouses, each chosen to match different needs and skill levels.